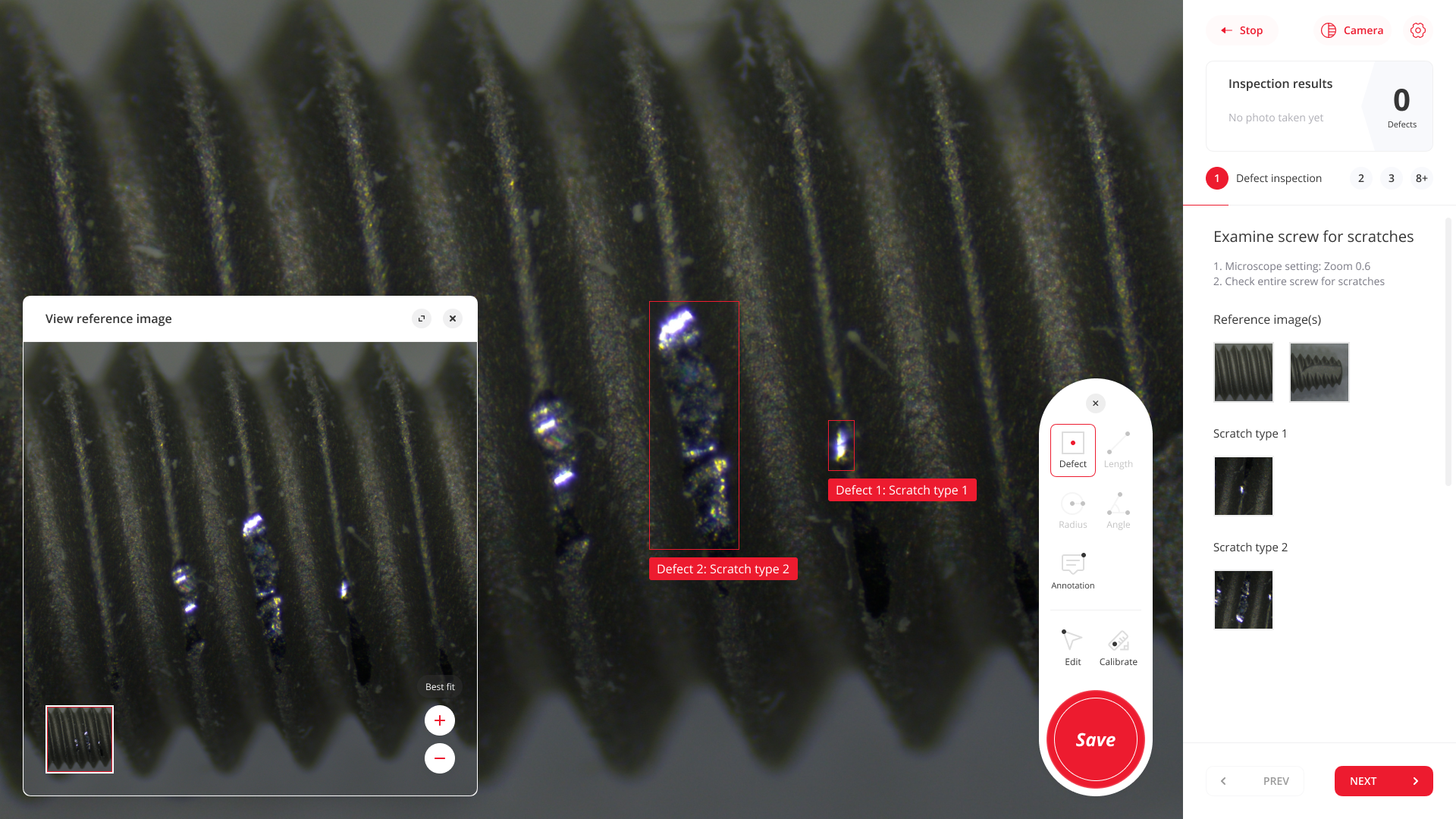

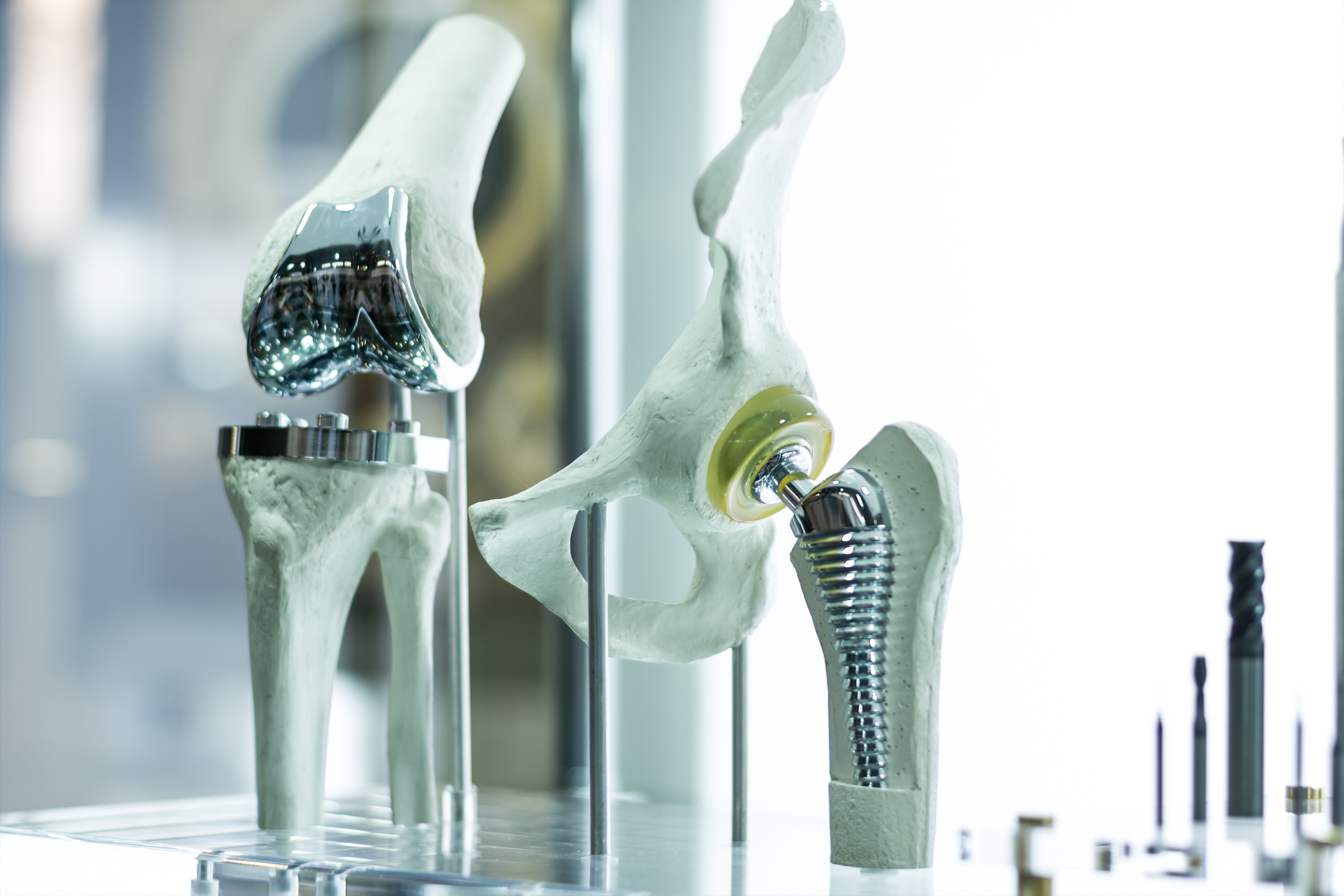

Elevate your inspection workflow for medical devices - digital, consistent and traceable.

Date: 18 May | Time: 11 AM London / 12 PM Berlin / 03 PM Dubai

Elevate your inspection workflow for medical devices - digital, consistent and traceable.

Date: 18 May | Time: 11 AM London / 12 PM Berlin / 03 PM Dubai

Already Registered?

If you have previously registered for this event, please login below:

Register your details below